The manufacturing industry is undergoing a profound transformation with the advent of smart factories. These factories, equipped with advanced technologies and interconnected machinery, are changing the way products are produced and revolutionizing the efficiency and productivity of industrial processes. In this blog, we will explore the innovations in industrial machinery that are driving the future of smart factories.

The manufacturing industry is undergoing a profound transformation with the advent of smart factories. These factories, equipped with advanced technologies and interconnected machinery, are changing the way products are produced and revolutionizing the efficiency and productivity of industrial processes. In this blog, we will explore the innovations in industrial machinery that are driving the future of smart factories.

1. Internet of Things (IoT) integration

One of the key advancements in industrial machinery is the integration of the Internet of Things (IoT). IoT enables the connectivity of various devices and machines, allowing them to exchange data and communicate with each other in real-time. This connectivity allows for enhanced monitoring, predictive maintenance, and optimization of production processes. By collecting and analyzing data from various sensors and devices, smart factories can make informed decisions, optimize energy consumption, and prevent costly breakdowns.

2. Artificial Intelligence (AI) and Machine Learning

Artificial Intelligence (AI) and Machine Learning technologies are fundamental to the evolution of smart factories. Through AI algorithms and machine learning models, industrial machinery can process and analyze large volumes of data to identify patterns, optimize production processes, and make intelligent decisions. For instance, AI-powered robots can perform complex tasks with precision and adapt to changing conditions, improving efficiency and reducing errors on the factory floor.

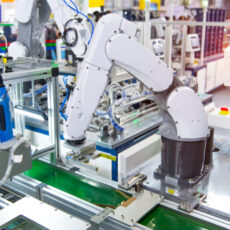

3. Robotics and Automation

Robotics and automation have been game-changers in modern manufacturing. Industrial robots equipped with advanced sensors and AI capabilities can perform repetitive and hazardous tasks with speed and accuracy. Automation of manufacturing processes not only increases productivity but also ensures worker safety by minimizing their exposure to dangerous environments. Moreover, collaborative robots, also known as cobots, can work side by side with human workers, augmenting their capabilities and enabling better cooperation between humans and machines.

4. Additive Manufacturing (3D Printing)

Additive Manufacturing, commonly known as 3D printing, is transforming the way products are designed and manufactured. This technology allows for the creation of complex geometries, reduces material waste, and enables on-demand production. With 3D printing, smart factories can minimize inventory, customize products, and accelerate the prototyping and production cycle. Additionally, this technology opens up possibilities for decentralized manufacturing, where products can be produced on-site, reducing transportation costs and the carbon footprint associated with long-distance shipping.

5. Augmented Reality (AR) and Virtual Reality (VR)

Augmented Reality (AR) and Virtual Reality (VR) technologies are increasingly being integrated into industrial machinery. AR offers real-time information overlay, providing workers with relevant instructions, data, and visual cues during manufacturing processes. VR, on the other hand, offers immersive simulations and training programs, allowing workers to practice their skills in a virtual environment, minimizing the risk of errors or accidents. These technologies enhance productivity, reduce training time, and improve overall safety within smart factories.

Summary

Innovations in industrial machinery are propelling the evolution of smart factories, bringing forth a new era of manufacturing. The integration of IoT, AI, and machine learning technologies allows for real-time data analysis, optimization, and predictive maintenance. Robotics and automation are transforming production processes, increasing efficiency, and ensuring worker safety. Additive manufacturing is enabling on-demand production and customization. Lastly, AR and VR technologies are enhancing productivity and safety on the factory floor. As these technologies continue to advance and become more accessible, the future of smart factories looks promising, promising increased efficiency, sustainability, and competitiveness for the manufacturing industry as a whole.

Got Questions About Industrial Machinery? Let Us Help!

Hydraulic Power Sales, Inc. is local manufacture, distributor, and service provider of hydraulics equipment based in Cordova, California. Since 1985, we have been providing hydraulic repair services, hose assemblies, and sales to businesses throughout northern California. We manufacture hydraulic engine systems and hydraulic cylinders while supplying other hydraulic equipment. We want to be your one source for all of your hydraulic/pneumatic needs. Give us a call today!