Hydraulic cylinders are essential components in a wide range of machinery and equipment, from construction machinery to industrial automation systems. These cylinders play a crucial role in providing linear motion and force in various applications. However, like any mechanical component, hydraulic cylinders can encounter issues that may affect their functionality and performance. In this blog post, we will discuss some of the common issues that may arise with standard hydraulic cylinders and provide some troubleshooting tips to help you address these problems effectively.

1. Leakage:

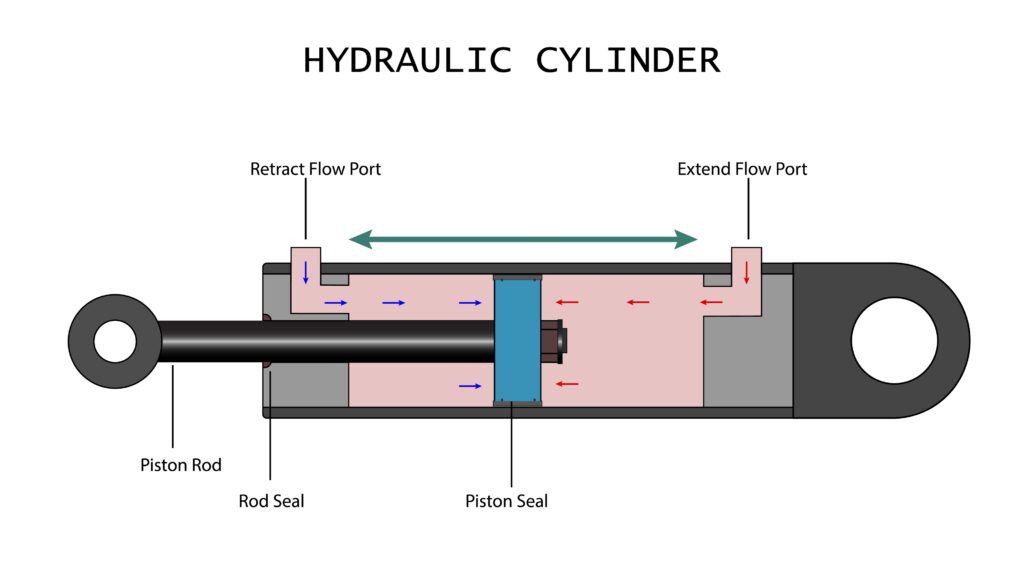

One of the most common issues with hydraulic cylinders is leakage. Hydraulic fluid leaks can occur at various points in the cylinder, including the rod seal, piston seal, or head gland. These leaks can result in a loss of hydraulic fluid, reduced efficiency, and potential contamination of surrounding components. To troubleshoot a leakage issue, inspect the cylinder for visible signs of fluid leaks, such as puddles of hydraulic fluid or wet spots. Check the seals and gaskets for wear or damage, and replace any faulty seals to resolve the issue. Additionally, ensure that the hydraulic fluid level is adequate and that there are no loose connections or fittings that could be causing the leak.

2. Slow or Erratic Movement:

Another common issue with hydraulic cylinders is slow or erratic movement. This can be caused by air trapped in the hydraulic system, improper fluid viscosity, or a malfunctioning control valve. To troubleshoot slow or erratic movement, check the hydraulic fluid level and ensure that it is clean and free of contaminants. Bleed any air from the hydraulic system by cycling the cylinder a few times to remove trapped air bubbles. If the issue persists, check the control valve for proper operation and adjust the flow control settings if necessary to regulate the speed of the cylinder movement.

3. Uneven Wear:

Uneven wear on the cylinder rod or piston can indicate an alignment issue or an improperly sized cylinder for the application. Uneven wear can cause premature failure of the cylinder and lead to performance issues. To troubleshoot uneven wear, inspect the cylinder rod and piston for signs of wear or damage, such as scoring or pitting. Check the alignment of the cylinder and ensure that it is installed correctly and operating within the specified parameters. If the cylinder is undersized for the application, consider replacing it with a properly sized cylinder to prevent further wear and damage.

4. Excessive Noise:

Excessive noise during cylinder operation can indicate a mechanical issue, such as worn or damaged internal components, loose fittings, or air in the hydraulic system. To troubleshoot excessive noise, listen for any unusual sounds coming from the cylinder during operation, such as banging, grinding, or screeching. Inspect the cylinder for loose fittings, damaged components, or signs of internal wear. Tighten any loose fittings and replace any worn parts to reduce noise levels. Bleed air from the hydraulic system if necessary and ensure that the hydraulic fluid is clean and at the proper viscosity to minimize noise during cylinder operation.

5. Overheating:

Overheating of a hydraulic cylinder can be caused by excessive friction, a blocked or restricted flow, or improper fluid viscosity. Overheating can damage internal components and reduce the efficiency and lifespan of the cylinder. To troubleshoot overheating, monitor the temperature of the hydraulic fluid during cylinder operation and look for signs of overheating, such as hot and discolored hydraulic fluid. Check for any restrictions in the hydraulic system that may be causing excessive pressure and temperature buildup. Ensure that the hydraulic fluid is clean and at the proper viscosity to prevent overheating. If necessary, adjust the flow control settings to regulate the flow and reduce heat generation in the cylinder.

Summary

Troubleshooting common issues with standard hydraulic cylinders is essential to ensure proper functionality and performance. By addressing issues such as leakage, slow or erratic movement, uneven wear, excessive noise, and overheating promptly and effectively, you can prevent more serious problems from arising and prolong the lifespan of your hydraulic cylinders. Regular maintenance, inspection, and troubleshooting of hydraulic cylinders can help you identify and resolve issues before they escalate and impact the operation of your machinery and equipment. Remember to consult the manufacturer’s guidelines and seek professional assistance if needed to address more complex hydraulic cylinder issues.

Got Questions About Industrial Machinery? Let Us Help!

Hydraulic Power Sales, Inc. is local manufacture, distributor, and service provider of hydraulics equipment based in Cordova, California. Since 1985, we have been providing hydraulic repair services, hose assemblies, and sales to businesses throughout northern California. We manufacture hydraulic engine systems and hydraulic cylinders while supplying other hydraulic equipment. We want to be your one source for all of your hydraulic/pneumatic needs. Give us a call today!