Hydraulic valves play a crucial role in controlling the flow and pressure within a hydraulic system. Understanding their function and importance is essential for anyone involved in hydraulic machinery, from engineers to operators. In this comprehensive guide, we’ll delve into the fundamentals of hydraulic valves, exploring their purpose, types, and significance in various applications.

What Are Hydraulic Valves?

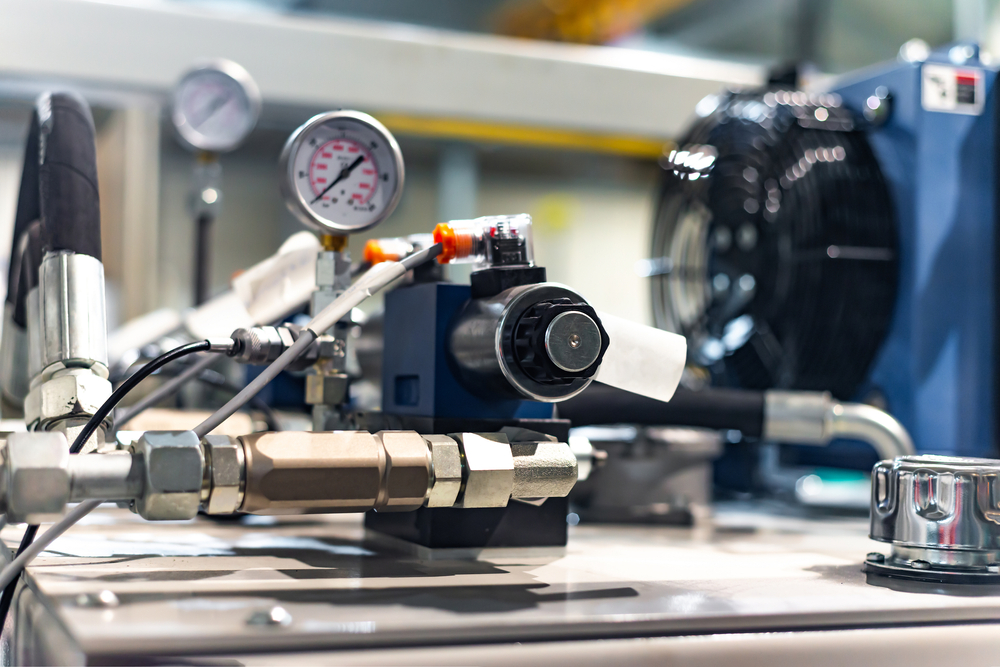

Hydraulic valves are mechanical devices designed to regulate the flow of fluid within a hydraulic system. They control the direction, pressure, and flow rate of the hydraulic fluid, thereby dictating the movement and operation of hydraulic actuators such as cylinders and motors. Essentially, hydraulic valves act as gatekeepers, managing the transfer of energy within the system to achieve desired mechanical outputs.

Hydraulic Valves Basics

At their core, hydraulic valves operate based on the principles of fluid dynamics and control theory. The key components of a hydraulic valve include:

- Valve Body: This is the main structure housing the internal components of the valve and providing ports for fluid inlet and outlet.

- Internal Mechanism: Various types of mechanisms such as spools, poppets, or discs control the flow of fluid based on external inputs like pressure or electrical signals.

- Actuators: These components move the internal mechanism to open, close, or throttle the valve in response to control signals.

Types of Hydraulic Valves

Hydraulic valves come in a variety of types, each suited for specific functions and operational conditions. Some common types include:

- Directional Control Valves: These valves determine the direction of fluid flow within the system, enabling actuators to move in desired directions.

- Pressure Control Valves: They regulate the pressure levels within the hydraulic system to prevent damage and ensure efficient operation.

- Flow Control Valves: These valves manage the rate of fluid flow, allowing for precise control of hydraulic actuators’ speed and movement.

- Proportional and Servo Valves: Advanced valves that provide accurate and proportional control over flow, pressure, or direction, often used in sophisticated hydraulic systems.

Importance of Hydraulic Valves

Hydraulic valves are integral to the performance and safety of hydraulic machinery for several reasons:

- Control and Precision: They enable precise control over the movement and operation of hydraulic actuators, essential for applications requiring accuracy and repeatability.

- Safety and Reliability: Properly functioning valves ensure that hydraulic systems operate within safe pressure and flow limits, minimizing the risk of equipment damage or failure.

- Efficiency: By regulating fluid flow and pressure, hydraulic valves contribute to the overall efficiency of hydraulic systems, optimizing energy usage and reducing operational costs.

- Versatility: Different types of hydraulic valves cater to a wide range of applications across industries such as construction, manufacturing, agriculture, and aerospace, demonstrating their versatility and adaptability.

Conclusion

Hydraulic valves are fundamental components of hydraulic systems, serving critical roles in controlling fluid flow, pressure, and direction. Their diverse types and configurations accommodate various operational requirements, from basic directional control to precise proportional adjustments. Understanding the basics of hydraulic valves is essential for anyone involved in hydraulic system design, maintenance, or operation, ensuring efficient and reliable performance of machinery across different industries.

Whether you’re a seasoned engineer or someone new to hydraulic systems, grasping the importance and functionality of hydraulic valves is key to harnessing the full potential of hydraulic power in modern applications.

By mastering these fundamentals, you gain insights into how these valves translate hydraulic energy into mechanical work, driving productivity and innovation in hydraulic technology.

Remember, the next time you witness heavy machinery in action or marvel at the precision of hydraulic systems, you’ll appreciate the crucial role hydraulic valves play in making it all possible.

Got Questions About Industrial Machinery? Let Us Help!

Hydraulic Power Sales, Inc. is local manufacture, distributor, and service provider of hydraulics equipment based in Cordova, California. Since 1985, we have been providing hydraulic repair services, hose assemblies, and sales to businesses throughout northern California. We manufacture hydraulic engine systems and hydraulic cylinders while supplying other hydraulic equipment. We want to be your one source for all of your hydraulic/pneumatic needs. Give us a call today!