How To Select The Right Hydraulic Motor

The proper hydraulic motor selection is an important part of the hydraulic system design process. Selecting a hydraulic motor that does not fit the needs of the system can lead to problems.

Size

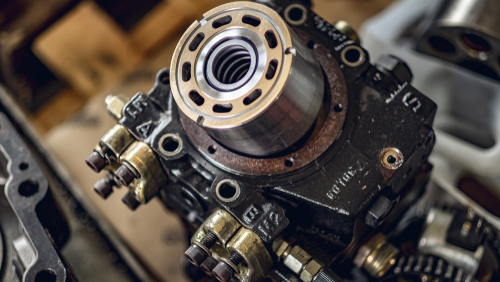

Hydraulic motors vary in size, depending on the fluid pressure and volume flow requirements of the system. Typical sizes range from 30 l/min (liters per minute) to 350 bar. Unlike pumps, which use valves to deliver hydraulic fluid to a motor, hydraulic motors contain a series of pistons that slide laterally on a flat surface inside the housing. As the motor output shaft rotates, the force of each piston applies a portion of its fluid pressure to the eccentric rotor. The size of a hydraulic motor is determined by determining the required torque and speed to achieve a specific load capacity. This information is used to determine the model with suitable ratings that will operate efficiently and effectively. It is important to determine whether the desired torque from the hydraulic gear motor is starting torque or running torque. This is because if the hydraulic gear motor requires starting torque, it may need a larger output shaft than if it required only running torque.

Load Capacity

If you have ever used a hydraulic cylinder to lift something, you know that the size of the cylinder can make all the difference in whether the load can be safely lifted or not. Choosing the right size can save you time and money by preventing a failed lift and the loss of material or equipment. In the same way, choosing the right sized hydraulic motor is crucial for your application to run correctly and safely. If you select a motor that is too small for your operation, it may not be able to produce the torque needed to operate the pump effectively, or the flow of fluid could be too low to meet your needs. In order to determine the right load capacity, you need to know how much the item being lifted is weighing and how long it will take to lift it. Then you can use this information to select the appropriate cylinder for your application.

Efficiency

When choosing a hydraulic motor for a system, efficiency is a factor to consider. Hydraulic motors are designed to operate at a very high power to size ratio. They also have the highest output torque in relation to their input force, making them ideal for applications that need to move large amounts of mass quickly. However, they are not as efficient as piston pumps. This is because hydraulic motors are not sized based on horsepower but rather on torque and speed. The resulting pump is less efficient than one that was sized correctly.

Noise

When selecting a hydraulic motor, it’s important to consider how noisy the system will be. Noise levels can be a serious issue and may even violate the law in some countries. One way to determine the right noise level is by measuring the sound from various points around the system. This will help you pinpoint the source of the problem and determine what steps need to be taken. In most cases, the main culprit of noise is the pump or other motor. However, the hoses and tubes can also cause excessive noise. In recent experiments, researchers discovered that changing the configuration of a hydraulic hose can cut pump noise by an average of 5 decibels. This is because long lines often serve as the primary path for pressure pulsations to spread throughout the structure of the hydraulic equipment and radiate noise from the hoses to other components in the power unit.