Unleashing Power and Efficiency: A Guide to Hydraulic Motors

Unleashing Power and Efficiency: A Guide to Hydraulic Motors

Hydraulic motors are one of the most efficient and powerful types of motors available in the market today. They are capable of delivering high torques at low speeds and are known for their ruggedness, durability, and ability to operate in harsh environments. In this blog post, we’ll explore the basics of hydraulic motors, their components and working principle, and some of their common applications.

What are hydraulic motors?

A hydraulic motor is a type of mechanical device that uses fluids to generate torque and rotational motion. Basically, it converts hydraulic energy into mechanical energy. These motors are widely used in industrial applications where heavy-duty equipment is required, such as construction machines, agricultural machinery, or in heavy-duty drilling rigs.

Hydraulic motors are classified into two categories based on their operating principle – rotary and linear. Rotary hydraulic motors are designed to provide a continuous rotational motion about an axis, while linear hydraulic motors are designed to produce a linear motion.

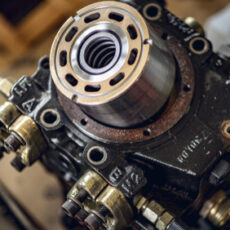

Components of hydraulic motors

The construction of a hydraulic motor consists of several parts that work in conjunction with each other. Some of the common components are:

1. Cylinder block – it is the primary housing of the hydraulic motor that contains the working fluid and the piston via which rotational motion is generated.

2. Pistons – these are reciprocating components that move back and forth within the cylinder block to create torque.

3. Rotor – the rotor is the rotating component that provides the mechanical output.

4. Valve spools – these valve spools control the flow of fluid to the piston, directing it to the right location within the cylinder block.

5. Bearings – hydraulic motors require bearings to ensure smooth and efficient operation.

Working principle of hydraulic motors

Hydraulic motors operate on the Pascal’s law of fluid mechanics, which states that pressure applied to a fluid in a closed system is transmitted equally in all directions. In a hydraulic motor, a high-pressure fluid is forced into the cylinder block through an inlet port. This pressure causes the piston to move, which, in turn, generates torque on the output rotor.

The rotary motion generated in the hydraulic motor is dependent on the number of pistons and the configuration of the rotor. These components work in tandem to provide efficient and reliable operation, with high torque and low speed.

Applications of hydraulic motors

Hydraulic motors find applications in numerous industries, from mobile equipment like tractors, cranes, and excavators to stationary equipment like wind turbines and industrial machinery. Some of the common applications of hydraulic motors are:

1. Agriculture – hydraulic motors are widely used in agricultural machinery, such as tractors and combines, to provide driving power to various attachments.

2. Construction – hydraulic motors are extensively used in construction machinery, including cement mixers, bulldozers, and excavators.

3. Industrial machinery – hydraulic motors are employed in industrial machinery such as press machines, conveyors, and – mills.

4. Mining – hydraulic motors are also used extensively in mining equipment such as drilling rigs, hydraulic shovels, and haul trucks.

Advantages of hydraulic motors

Hydraulic motors offer numerous advantages over other types of motors, including:

1. High torque – hydraulic motors provide high torques at low speeds, enabling them to perform heavy-duty tasks.

2. Ruggedness – hydraulic motors are designed to be durable and can operate in harsh environments, making them ideal for heavy machinery.

3. Low maintenance – hydraulic motors require minimal maintenance compared to other types of motors, reducing overall costs.

4. Energy efficiency – hydraulic motors are energy efficient, which results in less energy loss compared to other types of motors.

5. Versatility – hydraulic motors are versatile and can be used in a wide range of applications, including agriculture, construction, and industrial machinery.

Conclusion

Hydraulic motors are the workhorses of the industrial world, and their efficiency and power make them an excellent choice for heavy machinery applications. By understanding the components and operating principle of hydraulic motors, you can unleash their power and efficiency to get the job done efficiently and reliably. If you are in the market for a reliable and durable motor, consider investing in a high-quality hydraulic motor to ensure a reliable and efficient performance.