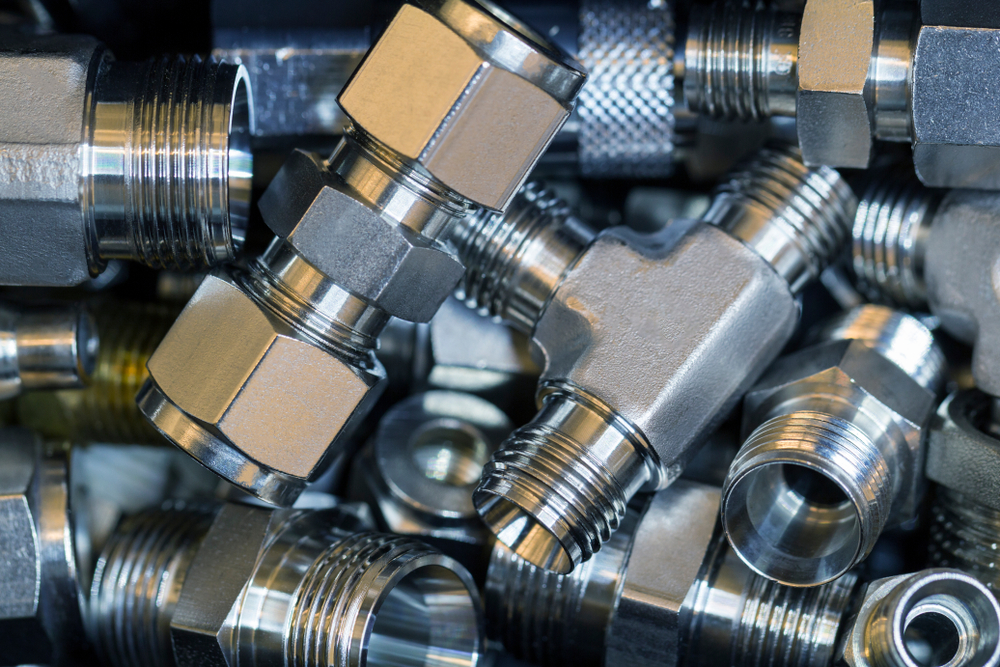

Hydraulic quick disconnects are vital components in fluid power systems, providing a means to connect and disconnect hydraulic lines quickly and safely. These connectors are designed to allow for efficient maintenance, equipment changes, and repairs without the need for specialized tools or extensive downtime. In this blog post, we will explore the different types of hydraulic quick disconnects, their features, and applications to help you make informed decisions for your hydraulic systems.

What Are Hydraulic Quick Disconnects?

Hydraulic quick disconnects, also known as hydraulic quick couplers, are devices that allow for the rapid and convenient connection and disconnection of hydraulic hoses or lines. They are used to join two hydraulic components, such as a hydraulic pump and a hydraulic cylinder, without the need to manually screw or unscrew fittings. This functionality is particularly useful in environments where hydraulic systems need to be frequently connected and disconnected.

Types of Hydraulic Quick Disconnects

Hydraulic quick disconnects come in various designs, each tailored to specific applications and requirements. Understanding these types will help you select the right quick disconnect for your needs. Here, we will break down the most common types of hydraulic quick disconnects.

1. Standard Hydraulic Quick Disconnects

Standard hydraulic quick disconnects are the most commonly used type and are designed for general-purpose applications. They typically feature a male and female coupling mechanism that ensures a secure connection. These connectors are available in various sizes and pressure ratings, making them versatile for different hydraulic systems.

Key Features:

- Easy to use

- Wide range of sizes and pressure ratings

- Suitable for general applications

Applications:

- Agricultural machinery

- Construction equipment

- Industrial hydraulic systems

2. Flat-Face Hydraulic Quick Disconnects

Flat-face hydraulic quick disconnects are designed to minimize spillage and air inclusion when disconnecting. They feature a flat-face design that allows for a clean separation of the hydraulic fluid, reducing the risk of contamination and fluid loss. This design also provides a more secure connection and is less prone to leakage compared to other types.

Key Features:

- Minimal fluid spillage

- Reduced air inclusion

- Secure connection

Applications:

- Mobile equipment

- Aerospace industry

- High-pressure hydraulic systems

3. Pioneer Hydraulic Quick Disconnects

Pioneer hydraulic quick disconnects are known for their robust design and high durability. They are typically used in demanding environments where reliability and resistance to harsh conditions are critical. Pioneer disconnects are available in various configurations, including single and double shut-off designs.

Key Features:

- High durability

- Suitable for harsh environments

- Available in single and double shut-off options

Applications:

- Heavy-duty construction equipment

- Mining machinery

- Agricultural machinery

4. Auto-Lock Hydraulic Quick Disconnects

Auto-lock hydraulic quick disconnects feature a locking mechanism that automatically engages when the connectors are mated. This ensures a secure connection without the need for manual locking or additional tools. Auto-lock disconnects are ideal for applications where ease of use and reliability are essential.

Key Features:

- Automatic locking mechanism

- Easy to connect and disconnect

- No additional tools required

Applications:

- Mobile equipment

- Industrial machinery

- Automotive hydraulic systems

5. Threaded Hydraulic Quick Disconnects

Threaded hydraulic quick disconnects use a threaded coupling mechanism to secure the connection between hydraulic lines. These disconnects are designed for high-pressure applications and are known for their strong and leak-proof connections. The threaded design ensures a tight fit and is suitable for systems where vibration or movement could otherwise cause disconnection.

Key Features:

- High-pressure capability

- Strong and leak-proof connection

- Suitable for vibrating applications

Applications:

- High-pressure hydraulic systems

- Industrial machinery

- Construction equipment

Factors to Consider When Choosing Hydraulic Quick Disconnects

Selecting the right hydraulic quick disconnect involves several considerations to ensure compatibility and performance. Here are some key factors to keep in mind:

1. Pressure Rating

Ensure that the hydraulic quick disconnect you choose has a pressure rating that matches or exceeds the pressure requirements of your hydraulic system. Using a disconnect with an inadequate pressure rating can lead to failure and potential safety hazards.

2. Size and Flow Rate

The size of the quick disconnect should match the size of the hydraulic hoses or lines it will connect. Additionally, consider the flow rate requirements of your system to ensure that the disconnect provides adequate flow without causing restrictions.

3. Material and Construction

The material and construction of the hydraulic quick disconnect affect its durability and resistance to environmental factors. Common materials include steel, stainless steel, and aluminum. Choose a material that is suitable for the operating conditions, such as exposure to corrosive substances or extreme temperatures.

4. Connection Type

Different hydraulic quick disconnects use various connection mechanisms, such as threaded, push-to-connect, or bayonet fittings. Select a connection type that aligns with your system’s requirements and ease of use.

5. Seal Type

The seal type in a hydraulic quick disconnect plays a crucial role in preventing leaks and maintaining system integrity. Common seal types include O-rings and flat seals. Ensure that the seal material is compatible with the hydraulic fluid used in your system.

Conclusion

Understanding the different types of hydraulic quick disconnects and their applications is essential for selecting the right components for your hydraulic systems. By considering factors such as pressure rating, size, material, connection type, and seal type, you can ensure reliable and efficient operation of your hydraulic equipment. Whether you need standard disconnects for general applications or specialized options for high-pressure or harsh environments, there is a hydraulic quick disconnect designed to meet your needs.

For more information on hydraulic quick disconnect options and their applications, consult with a hydraulic systems expert or supplier to find the best solutions for your specific requirements.

Got Questions About Industrial Machinery? Let Us Help!

Hydraulic Power Sales, Inc. is local manufacture, distributor, and service provider of hydraulics equipment based in Cordova, California. Since 1985, we have been providing hydraulic repair services, hose assemblies, and sales to businesses throughout northern California. We manufacture hydraulic engine systems and hydraulic cylinders while supplying other hydraulic equipment. We want to be your one source for all of your hydraulic/pneumatic needs. Give us a call today!