The hydraulic industry is undergoing a technological revolution, introducing advanced solutions that enhance efficiency, sustainability, and productivity. This year, the sector has witnessed groundbreaking developments in hydraulic innovations that are transforming how industries such as manufacturing, construction, agriculture, and automotive operate. Driven by digital transformation, environmental sustainability goals, and the demand for smarter, more reliable systems, these changes are redefining the future of hydraulic systems. From intelligent automation to hybridized solutions, the focus is on combining performance with energy efficiency. Below, we explore the most significant hydraulic technology trends shaping the industry this year.

The Rise of Smart Hydraulic Systems

One of the most significant hydraulic innovations reshaping the industry is the rapid adoption of smart hydraulic systems. These systems integrate advanced sensors, data analytics, and IoT connectivity to monitor performance in real time and optimize operations. Unlike traditional hydraulic setups, which often rely on manual checks and static settings, smart hydraulics bring adaptive intelligence to machinery. Operators can now access predictive maintenance insights, remotely control systems, and receive instant alerts when performance deviates from set parameters.

This advancement has had a profound impact on industries where precision and uptime are critical. For example, in manufacturing plants, smart hydraulics can automatically adjust pressure and flow rates to match operational demands, reducing energy waste while increasing productivity. Similarly, in construction and mining, smart systems enhance safety by monitoring structural loads and preventing equipment failures. This year’s developments in embedded AI have further elevated these systems, enabling real-time decision-making without human intervention. As companies continue to embrace Industry 4.0 practices, smart hydraulic systems are becoming the standard, driving efficiency and innovation across multiple sectors.

Advancements in Electro-Hydraulics

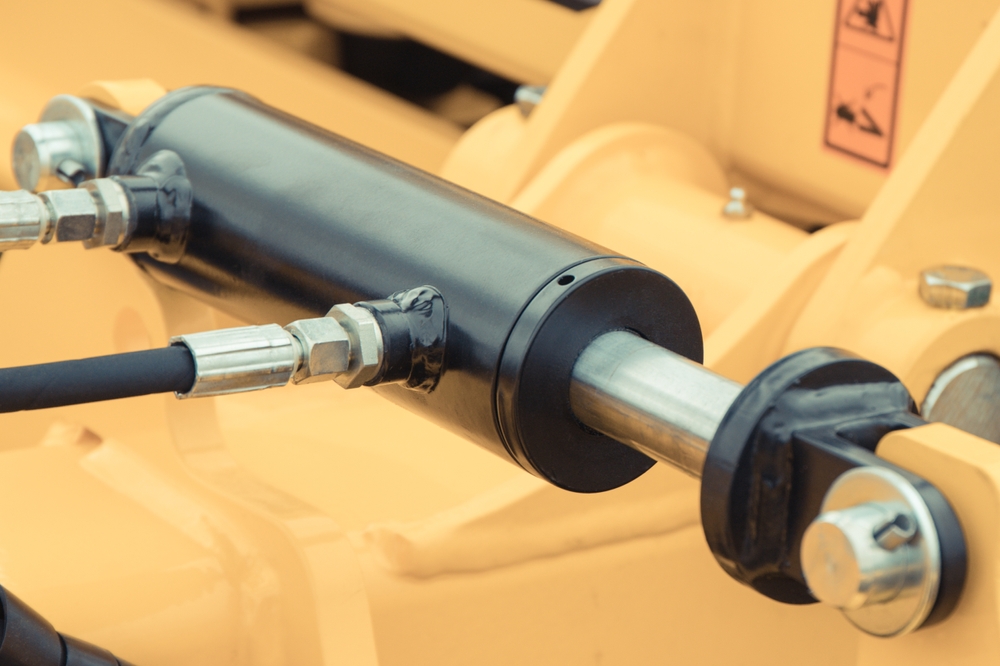

Another major trend shaping hydraulic technology this year is the rise of electro-hydraulics, a cutting-edge integration of hydraulic power with electric control. Electro-hydraulics combine the force and durability of hydraulics with the precision and responsiveness of electronic controls, offering a hybrid solution that optimizes both performance and sustainability. These systems have become increasingly popular in industries requiring fine control over movements, such as aerospace, automotive manufacturing, and robotics.

In the automotive sector, electro-hydraulics are being leveraged to power electric and hybrid vehicle systems while reducing energy consumption and emissions. The construction industry is also experiencing a shift, with equipment manufacturers adopting electro-hydraulic actuators to deliver smoother, more responsive operations and better fuel economy. Additionally, this technology has led to significant improvements in environmental sustainability by lowering noise levels and minimizing fluid leakage risks compared to conventional systems.

This year, innovations in electro-hydraulic systems have also focused on integrating machine learning algorithms, enabling them to adapt to different load conditions in real time. These intelligent capabilities not only reduce wear and tear but also improve overall system longevity, providing cost-effective solutions for industries transitioning to greener, smarter operations.

Hydraulic Technology Trends Driving Energy Efficiency

Sustainability has emerged as a central theme across hydraulic technology trends, with manufacturers prioritizing energy efficiency and reduced environmental impact. Governments and industries worldwide are introducing stricter emissions standards, forcing equipment developers to rethink traditional designs and adopt eco-friendly solutions. Modern hydraulic systems are increasingly being engineered with energy-saving pumps, regenerative technologies, and advanced power-on-demand systems to minimize energy waste.

One of the most noteworthy innovations this year is the implementation of variable-speed drive technology in hydraulic pumps. These systems automatically adjust power consumption based on operational demand, significantly reducing energy usage compared to constant-speed pumps. Additionally, closed-loop hydraulic systems are becoming more prevalent, recycling fluid within the system and reducing the overall volume required. These advancements not only lower operational costs but also help industries comply with evolving sustainability regulations.

Another trend driving energy efficiency is the integration of hybrid power systems. By combining traditional hydraulics with electric and battery-driven components, industries can achieve a balance between high power output and energy conservation. These hybrid solutions are particularly beneficial in mobile equipment and heavy-duty vehicles, where maximizing fuel economy is essential without compromising performance. This dual-focus approach is positioning hydraulic innovations at the forefront of the global sustainability movement.

The Role of Automation and AI in Hydraulic Innovations

Artificial intelligence and automation are transforming hydraulic technology by making systems smarter, faster, and more autonomous. With the rise of connected devices and advanced analytics, modern hydraulic systems are no longer limited to manual control or basic automated sequences. Instead, they can analyze data in real time, adapt to changing operating conditions, and make intelligent decisions without human intervention.

This year, we’ve seen significant progress in AI-driven diagnostics, allowing hydraulic systems to detect early signs of malfunction before failures occur. Automated algorithms monitor parameters such as pressure, temperature, and fluid quality, enabling proactive maintenance scheduling that minimizes downtime and repair costs. In industries like aerospace and automotive manufacturing, where precision is non-negotiable, these advancements are delivering unprecedented levels of reliability and efficiency.

Moreover, robotics powered by AI-integrated hydraulics are revolutionizing material handling, assembly lines, and agricultural equipment. These systems enable smoother, more precise movements while reducing human fatigue and operational risks. As industries increasingly adopt machine learning techniques, hydraulic systems are expected to evolve into fully self-optimizing platforms capable of continuously improving performance based on collected operational data.

Future Outlook for Hydraulic Innovations

Looking ahead, the future of hydraulic innovations points toward greater sustainability, connectivity, and adaptability. Emerging technologies such as digital twins are expected to transform system design and testing, allowing engineers to simulate hydraulic system performance under varying conditions before deployment. This approach reduces development costs and accelerates innovation cycles.

We are also seeing a growing focus on integrating hydraulic systems into fully electrified ecosystems, particularly in construction, agriculture, and transportation sectors. With the increasing adoption of autonomous vehicles and smart factories, hydraulics will need to seamlessly interact with AI-powered control systems and IoT-based monitoring platforms. In addition, we can expect further breakthroughs in eco-friendly hydraulic fluids, improved material durability, and compact system designs optimized for high-performance applications.

As industries move toward smarter and greener technologies, companies that embrace these hydraulic technology trends will be better positioned to maintain competitive advantages. From smart hydraulic systems and electro-hydraulics to energy-saving innovations and AI-driven automation, the future of hydraulics is shaping a new era of industrial performance.

Conclusion

The hydraulic industry is experiencing a transformative shift, driven by cutting-edge innovations that blend intelligence, sustainability, and efficiency. This year’s advancements in smart hydraulic systems, electro-hydraulics, and AI-powered automation are setting the stage for a future where hydraulic solutions are more adaptive, energy-efficient, and environmentally responsible. As industries worldwide continue to prioritize productivity and eco-conscious operations, these hydraulic innovations are becoming indispensable across manufacturing, construction, agriculture, and beyond. The integration of advanced control systems, IoT connectivity, and hybrid power solutions is redefining how modern equipment operates, ensuring optimal performance while meeting evolving environmental standards. For companies looking to remain competitive in this fast-changing landscape, staying informed about the latest hydraulic technology trends is no longer optional—it’s essential. The future of hydraulics promises smarter, greener, and more resilient systems that will power the next generation of industrial progress.

Got Questions About Industrial Machinery? Let Us Help!

Hydraulic Power Sales, Inc. is local manufacture, distributor, and service provider of hydraulics equipment based in Cordova, California. Since 1985, we have been providing hydraulic repair services, hose assemblies, and sales to businesses throughout northern California. We manufacture hydraulic engine systems and hydraulic cylinders while supplying other hydraulic equipment. We want to be your one source for all of your hydraulic/pneumatic needs. Give us a call today!